Conveyor systems and conveyor belts

There are two main

industrial classes of conveyor systems;

- Those used in general material handling such as moving boxes along in a factory.

- Those used in bulk material handling such as transporting industrial and agricultural materials or products, such as grain, coal, ores, etc. they are generally used in outdoor locations.

Conveyor belts

Conveyor belts were used since the 19th

century. In 1892, Thomas Robins began a series of inventions which led to the

development of a conveyor belt used for carrying coal, ores and other products.

In general, a conveyor belt consists of two end

pulleys, with a continuous loop of material that rotates round these pulleys. The

pulleys are used for providing the

drive to the belt through a drive unit gear box powered by an electric motor.

The forward movement of the belt is as a result of the friction generated between the pulley and the belt.

One or both of the pulleys can be powered and it also helps to provide proper tension to the belt.

The powered pulley is called the drive pulley

while the un-powered pulley is called the idler. Most of the belts in material

handling is made of two layers, the top layer called the carcass which provides

linear strength and shape and the bottom layer called the cover. The carcass is

often a can be made from materials like cotton, plastic web or roots and mesh.

The cover can be made from rubber or plastic compounds.

Nowadays, the material used for making a conveyor belt

is determined by its application and can be made from materials like PVC, cotton,

canvas, leather, polyester, neoprene, nylon, urethane, polyurethane, rubber,

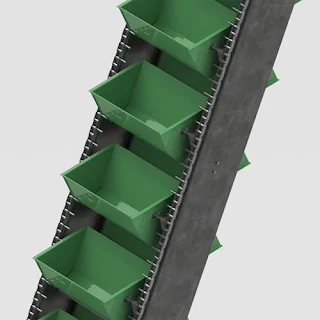

silicone and steel are commonly used in conveyor belts. The figure below shows

an example of a conveyor belt.

|

| A view of a belt conveyor |

There exist a

variety of belt conveyors which are used depending on the domain of

application. They include the:

- wire belt conveyor

- plastic belt conveyor

- wire mesh conveyors

- bucket Conveyor

- spiral conveyors

- pneumatic conveyors

- screw conveyor or auger conveyor

- etc.

These conveyor belts may be of roller, flat, modular, cleated, curved or inclined type.

Reference:

[1] Olome Baudouin E. "Design and realization of an automatic industrial sorting machine", University of Bamenda, July 2019.

[2] International journal of advanced research in science and engineering vol no. 07, special issues no.01 march 2018