Design and realization of an automatic industrial sorting and counting machine

In

order to present this project, this dissertation is divided into five chapters.

- Chapter 1: General introduction of the system.

- Chapter 2: Review of related literature on the project and contents related to the project.

- Chapter 3: Technological study of components (theoretical study, dimensioning of components and choice criterion).

- Chapter 4: System simulation and practical implementation.

- Chapter 5: Difficulties encountered, recommendations, future scope, and conclusion.

Get

complete PDF, simulation, codes, and PCB design. Link at bottom

Problem statement

In

modern industry, the sorting of items or products into various categories by an

automated system is of great importance in order to have competitive advantages

in production speed, efficiency, production value and labour cost.

This

project involves designing and realizing an automated industrial sorting machine

which is able to sort and count the number of items into their various categories.

For example, in an industry producing soaps of different sizes, the sorting

machine can be used to group these soaps into their various categories.

Scope and objectives of the study

The

objectives of this project is:

- Sorting of two items on the basis of their respective height. With the height of the smaller item ranging from 3.5cm to 9cm and the bigger item ranging from 9.1cm to 20cm.

- Counting the number of items sorted.

Using

a PIC 16F877A microcontroller to implement the control of this system.

Overview

The

machine consist of a conveyor belt which carries the items from the manufactured

end, passing through a detector made of IR sensors which detects the category

of the item. The item is then passed to the sorting compartment designed at one

end of the conveyor belt in order for the items to be sorted. Once at the

sorting compartment of the conveyor belt, the item is sorted into its category.

The sorting is done with the use of two DC motor controlled linear arm actuators

each corresponding to a specific category of item. The linear actuator which ejects

in a single axes directs the item through a specific route into the next process

or receptor. An LCD is used to display the number of items being sorted.

System block

diagram

System block diagram

Components used

The

components used in designing this system are:

- PIC microcontroller

- Infra-red sensors

- DC Motors

- Motor driver

- Liquid crystal display

- Resistors, capacitors, diodes, etc.

- Conveyor belt structure (Plastic belt, bearings, roller pipes, wooden/metallic framework)

Dimensioning of system components

Available

in complete PDF

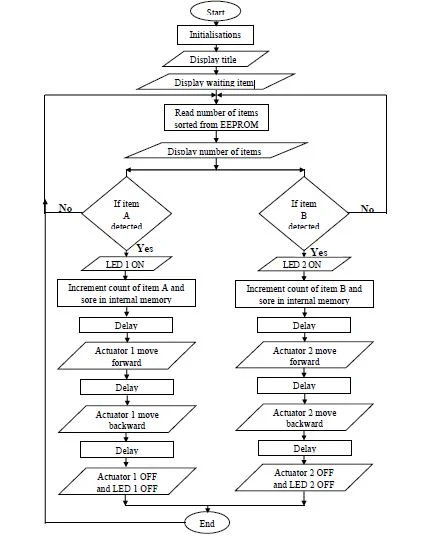

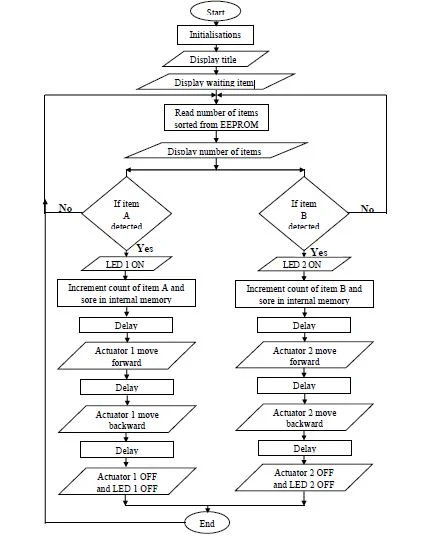

Flow chart

System flow chart

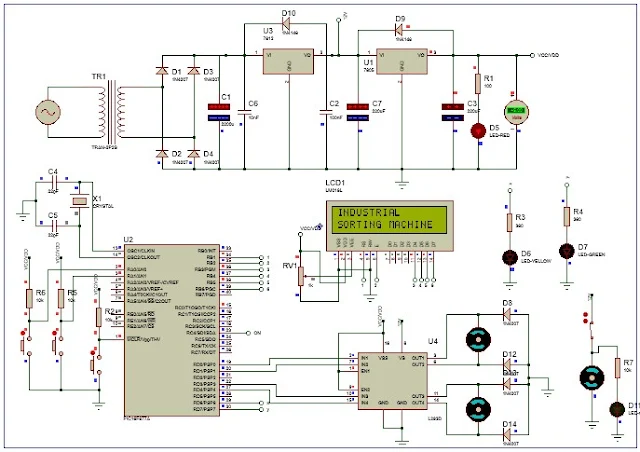

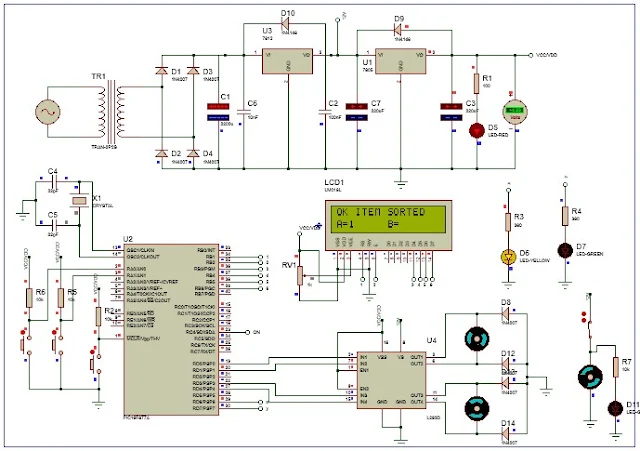

Circuit diagram and System simulation

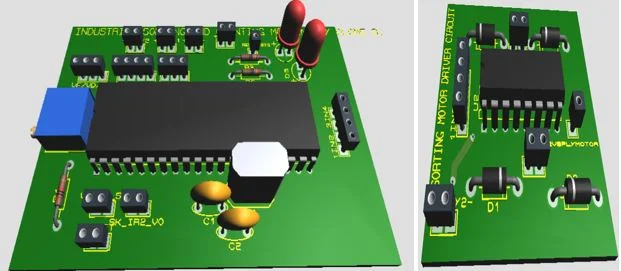

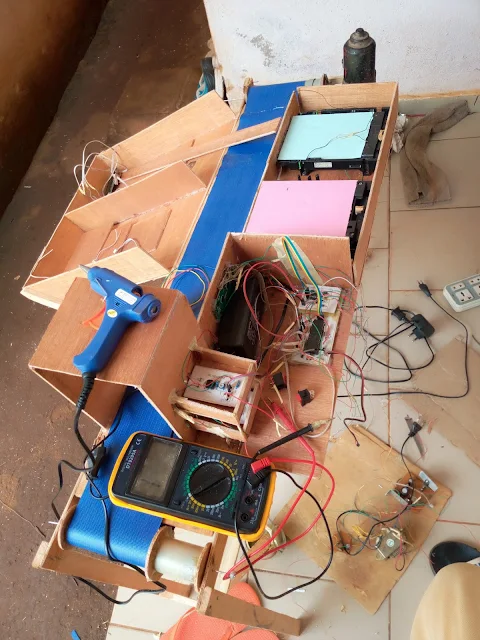

Realised piece

|

| Industrial sorting and counting machine |

Click Here to get complete PDF, simulation, code and PCB design

Reference: Olome B.E. "design and realisation of an automatic industrial sorting machine", university of Bamenda, July 2019