Direct On Line semi-automatic Starting forward and reversed rotation

Direct on line starting is a method generally used to start three phase induction motors with power less than or equal to 10KW.

Circuit diagram of direct on line starting:

Operating principle:

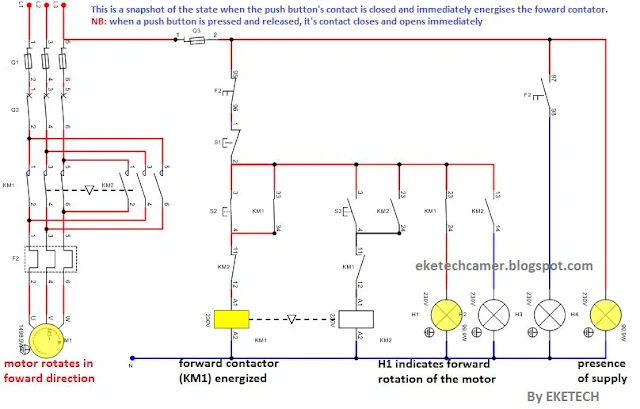

When

the fuse isolator is closed, an action on the start push button S2 energises

the contactor KM1 which closes the main contacts of the contactor, closes its

hold on contact, opens the interlock on kM2 (so that KM2 should not be

energized) and closes the open contact of KM1 to which the lamp H1 is connected. The motor

rotates in the forward direction and the lamp H1 shines which indicates the

motor is running in the forward direction.

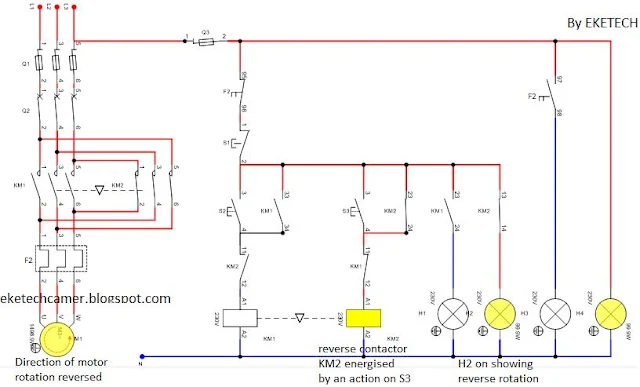

To

reverse the direction of rotation of the motor, the motor must first be stopped

by pressing S1.

For

reverse rotation, an action on the reverse push button S3 energises the contactor

KM2 which closes the main contacts of the contactor, closes its hold on contact, opens the interlock on KM1 (so that KM1 should not be energized) and closes

the open contact of KM2 to which the lamp H2 is connected. The motor rotates in the reverse

direction and the lamp H2 shines which indicates the motor is running in the reverse

direction.

The chronogram below shows how the pulse created by push button S3 energizes the reverse contactor and puts ON H2.

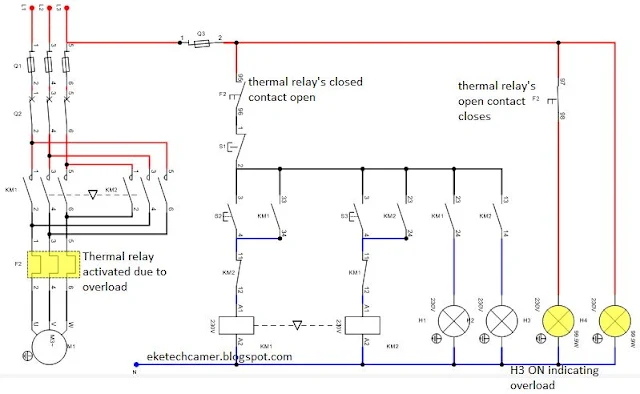

In

case of prolonged overload, the thermal relay’s normally closed contact (NC F2) opens and the normally opened contact of F2

to which the lamp H3 is connected closes and the lamp shines which indicates

the presence of the fault.

The

lamp H4 indicates the presence of supply.